One of the best things about our Llif-Flow R&D for Pontio’s Synthesis project is the number of serendipidous happenings. Like finding out that Iolo Price, AV/C & IT Technician at Pontio, is also a marble maker.

So, flowing with the flow of serendipity, so to speak, my collaborators Lisa Hudson and Jonathan Malarkey and I went to visit Iolo in his marble making shed in his garden in Caernarfon to watch him at work (to the lovely sounds of Jon Hopkins in the background).

It turns out that the construction of a marble shares many charactistics of those of constructing of marble runs for Llif-Flow: it combines skills in of art and science, and involves strong upper arm muscles and a great deal of patience. Things can go wobbly at any point.

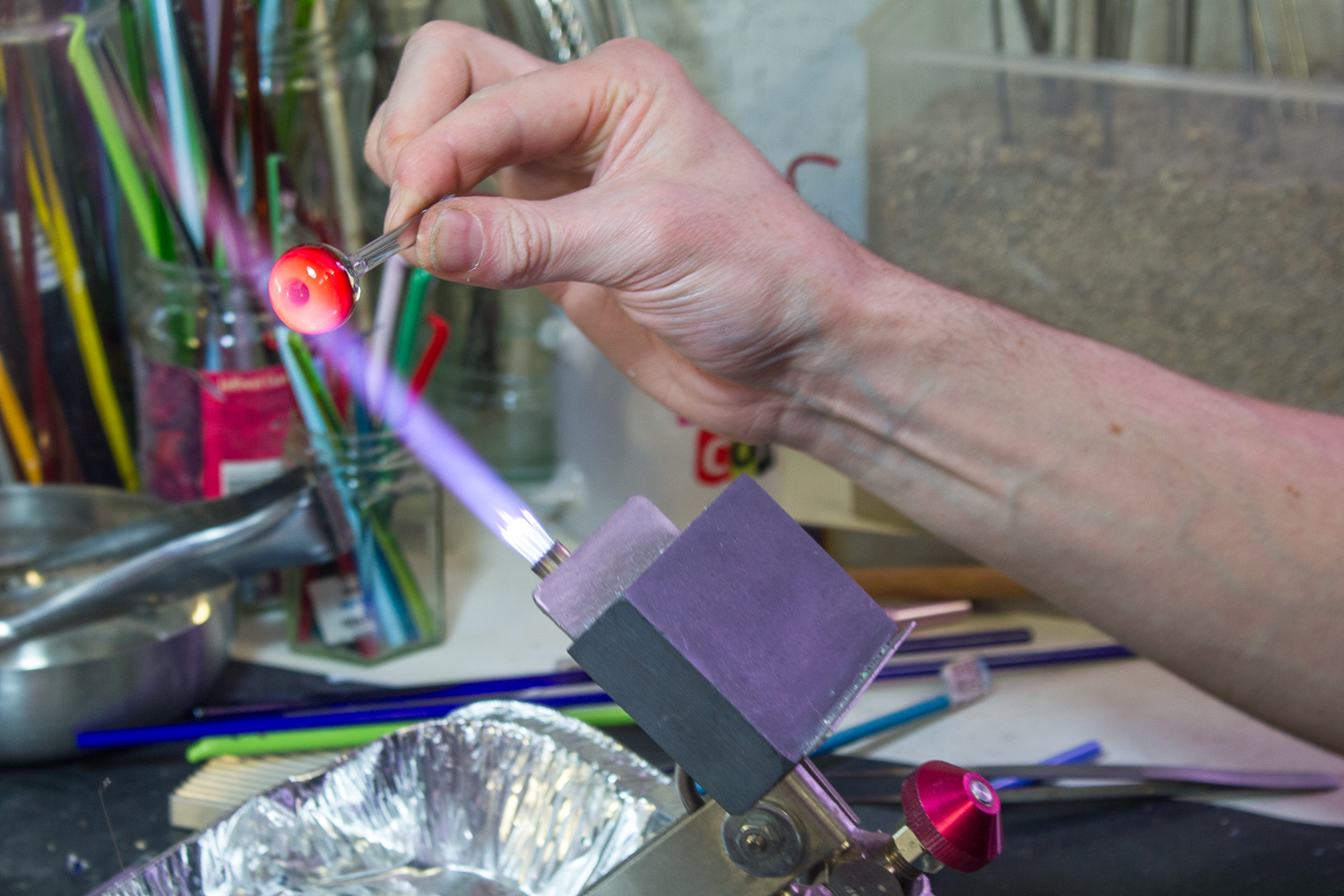

Making a marble the Iolo way involves making it in two halves. Each half begins life with the melting of an end of a glass rod while rotating it (more serendipity: vortices/spirals are a recurring theme in our Llif project), so that glass collects in a blob at the end.

This is glowing red hot blob is shaped in a marver, repeatedly heating and rounding...

Once one half is nice and round, decoration can be added with blobs from other glass rods, adding sparkly bits and usuing small torture-like instruments to distress it.

The second half (made with a clear glass rod in this marble) goes through the same process and the two halves are pushed together.

The process of decorating, reheating and shaping, continues, transfering one side to the other using glass rods, backwards and forwards until it is perfectly smooth.

The camera likes the view through the special marble-making glasses

It is then grabbed by something that resembles a Japanese head massager, and plunged into a can of vermiculite on a low heat, so it cools really slowly to avoid cracking. Unfortunately in the excitement of the moment, I didn't get a photo of this bit, but if you watch this video we've made for the project, you'll see it in action (about half way through):

And then (and this really was the best bit for me), Iolo offered to let me make my own marble! So after my welsh class last Thursday (for which I park on Iolo’s street), I popped in to have a go. I did not have high expectations - I was pretty sure it’d be all over the place, messy, blobby and not at all marble like. But look! Here is my marble about to be released while I take a quick shot of it, in my special marble-making glasses.

A long tradition

I now feel the latest recruit into a long line of marble makers: In a book that Iolo has lent me, ‘the Magical World of Marbles’, it says that marbles have been found in the pyramid tombs of Egyptian kings, and in finds from Aztecs, Hopewell Native Americans, Ancient Greece and Romans. The Victorians loved them, making clay ones they called clays or‘commies’ (the common everyday marbles children used for play), coloured in the tans, reds and browns of the clay from which they were made.]

Looking online, it seems that commercial marble-making is very different, involving continual rolling of the hot marble: You can see a short video of how they do it here. And those with a handy furnace can do very complex things see here (thanks to Freya Lawton for the link).

We’ll have a selection of marbles, including the one I made, together with Iolo's marble making equipment in a display in the foyer at Pontio from Tuesday next week. Its our 'dress rehearsal' tomorrow (probably without the dress bit) for the show on 3rd July (2-6pm). I'll get to see my marble for the (first time since it was plunged into its vermiculite cooler) because Iolo is coming in to do our AV and IT. Edrych ymlaen!!

The Llif collaboration, Jonathan, Lisa and I reflected in Iolo's vortex marble. Lisa suggested it could be our first album cover?!